|

| The "Brain Box", a ZF/Mathers MicroCommander 585; the Servos & Physical Cable Connections Are Behind the Printed Circuit Board. |

In

the days following the electronic throttle (and gear)

failure we began pursuing answers…but we weren’t finding anything

definitive. Immediately after the event

Rick had tested the electronic throttle station in the pilot house and found it

nonresponsive – dead, unable to take control at that location. But by the following day (Tuesday, 17-September) ALL THREE

throttle stations were operating normally once again. He ran the engines for a few hours to heat up

the engine room – wondering if the “brain box” for the electronic throttles,

which is located in the engine room, might be succumbing to heat related issues. But after retesting the throttles following the

heat soak, all stations again worked normally.

The

next day, Wednesday, 18-September,

Rick called on Ross Lund of Classic Yacht Service to visit the boat and assess

the electronic throttle system, but absent any active misbehavior that would

not be an easy task. No electrical

issues were found….voltage checked out at 13.3 volts at the control box, there

was no corrosion there, and all but one of the wire terminals were tight. The bare ground wire for “station 1” looked a

little ragged, so Rick removed & trimmed it, then re-attached it more

securely. Ross and his helper Jerry found

one potential issue with the physical cable running from the control box servo

actuator to the transmission – the cable length was about a quarter inch too

long, which theoretically at least might cause the servo control to keep trying

to push it further and issuing a fault when it couldn’t. They adjusted the cable appropriately.

The

more common failure in these types of electronic throttle controls is loose or

corroded connections at the throttle station(s). Given we experienced failures at both the fly

bridge and pilot house stations, Rick

didn’t think that was the likely cause – a fault at one station is isolated

from the other stations. But to be

cautious he spent some time examining the seven wire leads on the bottom side

of each throttle. The pilot house and

cockpit units checked out tight and corrosion-free; the fly bridge station

looked a little weathered and will require further evaluation and possibly

replacement.

|

| The Wiring on the Underside of the Throttle |

While

waiting on those parts the next step was to coordinate repairs to the physical

hull and rub rail damage Ghost Rider

incurred when it crunched the concrete piling following the throttle

failure. One of the go-to folks in this

area with good references for fiberglass and trim repairs is Mike Peters with

Brightworks. Mike inspected the damage

and thought the first pass should be wet sanding and buffing, so now we’re just

waiting on an opening in his busy schedule to see how that turns out.

We were also concerned that the boat’s bulbous bow might have made contact

with the docks; but on Friday,

20-September, our diver took an underwater spin around the boat and found

only a minor abrasion in the bottom paint there. That can wait for the next bottom paint job.

|

| The Water Accumulator Tank with a New Whale Fitting |

In

the midst all of this unplanned maintenance activity we encountered yet another

repair opportunity. During his routine below-deck

checks Rick discovered some standing water in the mid bilge area. The slope of that area isn’t ideal and thus

does not fully drain to the aft bilge where the pumps are located. Regardless, water doesn’t belong there, and

the “taste test” revealed it was fresh water.

Tracing such leaks back to the origin is usually a frustrating treasure

hunt – the source is rarely at or even near where the stuff ends up. But after using a shop vac to suck the mid

bilge dry Rick was able to trace a slow tell-tale water flow back to the water

accumulator tank on the port side of the engine room. The Whale compression fitting at the bottom

of that tank had a steady dribble – which of course turned into a wild fountain

fest when Rick fiddled with it.

After

scrambling to close off the water manifold valves and cutting the circuit

breaker to the water pump Rick got the wild spray under control – and then

toweled himself and the engine room dry.

It was then simple enough to drain the accumulator tank into a bucket

and replace the 15 mm Whale fitting with one of the spares we kept on

board. Re-pressurizing the system

revealed a good fix. To be on the safe

side Rick also checked the starboard side of the engine room where the fresh

water manifold resides and found the water-maker feed line leaking over there; re-tightening its connecting nut resolved that.

Coincidentally

we were also in the middle of cleaning and draining the FRP water storage

tanks. This is the first time we’ve had

to do that, as up to this year we had been on board and turning over the water

supply often enough that it couldn’t go stale. But after several months of non-use a mild

odor made it obvious that water quality had declined. A shock treatment of chlorine, followed by

draining, followed by three gallons of Camco’s Cleaner-Deodorizer and two more

fill & drain cycles got the job done.

That routine took most of a week, finishing up on Monday, 23-September. We

would leave three of the four tanks mostly empty (with a little of Camco’s

Freshener product added) until we began more active use of the boat in a couple

of months.

|

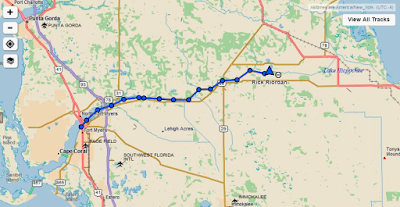

| The Tropics Were Still Very Active But Not in Our Immediate Vicinity |

In the meantime our weather had turned and stayed stunningly good. While the tropics were still chock full of named systems, none seemed to be threatening our area, and the same upper level air flow that was keeping them away from us had brought us dryer than normal air. It was a tad breezy and still warm, but we were enjoying abundant sunshine and reasonable (for us) humidity levels.

It

would have been fabulous boating weather.

Alas, that will need to wait until parts are procured, and repairs have

been made and sea-trialed. Hopefully we'll have more on that

in the next blog post.