Foreword:

There’s

nothing quite like a boat project (or two) to occasionally remind you that

you’re not near as handy as you previously thought. Or, perhaps, once were. If you ever wonder why some vessel owners

can seem rather humble at times, there is likely a causal connection to some

boat project. But since humility is a healthy sign of emotional maturity, we're OK with that.

There’s

nothing quite like a boat project (or two) to occasionally remind you that

you’re not near as handy as you previously thought. Or, perhaps, once were. If you ever wonder why some vessel owners

can seem rather humble at times, there is likely a causal connection to some

boat project. But since humility is a healthy sign of emotional maturity, we're OK with that.

Keeping ourselves and Ghost Rider healthy and happy while (still)

confined to port was the main goal for August, mainly to be able to move to our

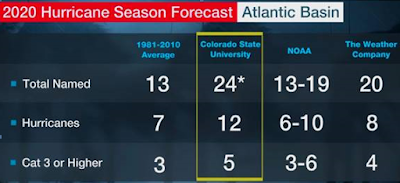

RFYC hurricane hole should the tropical weather patterns call for that. The official tropical forecast from the weather-guessers

had just recently increased the expected number of named storms to 24 (yikes)

and the expected hurricane count to 12 – which basically gave us the distinct

potential for the equivalent of two full storm seasons packed into one.

Secondary

goals included getting the dinghy davit (crane) back in operation and

completing the Racor fuel filter conversions. But neither of those was going very smoothly.

Break/Fix (Davit Update)

Both

Ross (of Classic Marine) and Rick had been active in the hunt for replacement

parts, mainly for the corroded hydraulic reservoir tank. As it turns out, the hydraulic pump, motor

and manifold assembly, which were theoretically still serviceable, have to be

matched to the opening fitment on the reservoir, which was most certainly not serviceable,

nor recoverable.

|

| The Crate Containing the New HPU for the Davit Was a Work of Art |

Basically that meant they had to be matched and replaced together as what’s known

as an HPU, or hydraulic power unit. Ross

had found a potential third party source, but wasn’t certain it would fit in

the limited space we had available in the base of the crane. Rick had contacted the manufacturer, Aritex,

located in Taiwan, and they committed to providing a factory original HPU for

two and a half Boat Units….plus $500 USD shipping via DHL air freight. And that’s the option we took. (If you’re curious, a whole new hydraulic crane

of similar capacity runs in the neighborhood of 20 Boat Units.)

The new HPU did not arrive here in the USA until 19-August, with the crate weighing in at

65 kilograms (143 pounds), and it took Rick 45 minutes to remove the 30 rather

beefy wood screws securing the top and four cross members that secured the

cargo inside. Overall measurements of

the new HPU matched up favorably with the old parts, but that’s where the

similarities ended. The motor was

actually bigger, the hydraulic manifold was mounted in a different location,

and electrical connections were lacking.

Ross took it to his shop where a lot of surgery is currently in progress

to see if we can make it work.

|

| The New HPU (Tank, Manifold, Valves & Motor) for the Davit |

Project

Work

Our

little “Racor conversion” project by now had morphed into something a bit more involved

than originally anticipated. After

installing the fire deflector on the wing engine’s primary filter, we

did the same for the transfer pump filter.

But after a couple days that one developed a slow leak. Out of an abundance of caution Rick decided

to replace all the remaining fuel bowls – after 18 years they were quite discolored – but

in the end the real key was to not over-torque the brass nut securing the heat

deflector shield to the plastic bowl...which would deform the sealing o-ring and allow fuel seepage.

|

| Rick Saved the Racor Conversion for the Genset for Last...It Had to be Completely Removed from the Fuel Lines & Bulkhead (Yellow Arrow) & then Disassembled (Red Arrow) to be Converted. |

In

the process we had also found that three of our filter brackets required adding

a 5/8” starboard backing plate to provide enough room for the increased diameter

of the heat deflectors. Rick also had to

remove and relocate two “Algae-X” filters for the wing engine and

generator. There was some added frustration

after discovering some of the Racor parts kits were missing o-rings or washers,

installation instructions on washer sequence sometimes differed between parts

kits, and at least one of the brass nuts used to attach the deflector to the

fuel bowl was threaded for the old-style bowls from the 1990’s.

Eventually

we got it all figured out and corrected.

We sourced most major parts from the Racor Store (LINK), but also tried Discount Racor (LINK), although they were painfully slow, delivered the wrong part,

and we saw nothing resembling a discount from them. As mentioned in our

previous post we sourced the UL rated brass draincocks and plugs from

McMaster-Carr (LINK), and in contrast

they were very prompt, and all of their stuff fit correctly. As an extra precaution Rick applied Loctite

565 to the male threads of those draincocks during assembly, but that was likely

overkill given their NPTF threads.

It

took a lot longer than expected, but it was very satisfying to have converted

the five Racor secondary fuel filters to a much safer, fire-tolerant

configuration.

|

| The Final Result -- All Five Racors Converted with Fire Protection Deflector Shields with Brass Draincocks & Plugs |

And

An “Aw Shit” Event

Lastly,

Rick managed to create a new maintenance opportunity during what should have

been a routine activity….cleaning the A/C strainer basket. But after removing said basket and while

cleaning it dockside with a high pressure water hose, he lost his grip on it and

the power of the water stream shot the thing off the dock like it was a Roman candle. And straight into the marina basin. He verified stainless

steel strainer baskets do not float, and that we had no spare on board.

|

| This is the Stainless Steel Strainer Basket for the A/C that Took a Dip in the Marina. Based on What West Marine Charges for One, It Belongs in a Bank Safe. |

We

did not want the boat to be without air conditioning in the stifling Florida humidity

for the several days it would take a reasonably priced replacement to arrive. So Rick found an overpriced one at the nearby

West Marine and got the system back in operation the same day. About a week later when the diver showed up

for Ghost Rider’s monthly

below-the-waterline cleaning, Rick asked him to scour the silty bottom, and he

did manage to retrieve the wayward strainer basket. So now we have a spare.

And Then There Was the Weather

The

first half of August was just the typical hot, humid and stormy stuff in south

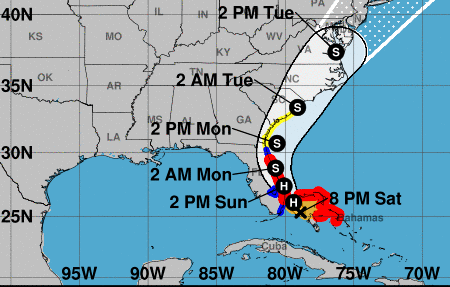

Florida. But the second half got more interesting. By 19-August the NHC was tracking the next two

systems, one in the western Caribbean (which would eventually become TS Marco)

and another in the western Atlantic (and would be dubbed Hurricane Laura.) While the former was not a factor for us, the

latter was initially forecast to take direct aim at our area, and potentially

at hurricane strength.

|

| The Original Forecast Track for Laura Was....Concerning |

River

Forest (our hurricane hidey hole) gave us some pretty short notice on a narrow arrival window; we decided

against moving the boat there for a variety of reasons, not the least of which

was low confidence in any of the early model calculations. It was becoming clear that even the best of the

predictive weather models were not dealing well with the changing climate

conditions. But we added extra lines and

fenders to Ghost Rider just in case

and kept careful watch on the evolving forecast.

|

| Eventually the Tracks for Both Marco & Laura Shifted Well to Our West |

We’re

now halfway through the tropical storm season, with only three months to go. Stay tuned, we're sure as hell paying attention.

....

|

| Ultimately Hurricane Laura Spooled Up to a Cat-4 Storm & Clobbered Louisiana on 27-August |

|

| After Laura Departed Four More Areas of Potential Development Appeared. Long Way to Go in This Season.... |

....