- Q:

How do you become a millionaire?

- A: Start out as a billionaire and then

buy a boat.

|

| The Match-box Sized Trackimo Device Locates Ghost Rider on a 24-by-7 Basis via Cellular & GPS Triangulation & Until Now Has Been the Only "Monitoring" Device Aboard the Boat. |

As

mentioned in a previous blog post, we had decided to pursue a

remote boat monitoring solution for Ghost

Rider. Up until this year we had

spent most of our time aboard, and any short separations were mostly when the

boat was on the hard for maintenance. So this hadn’t been a priority until very

recently when medical issues grounded us for a spell. While we had already

installed a GPS locating device with geo-fencing capabilities (Trackimo, which is similar to a LoJack device), and it gave us and the insurance

company a certain level of comfort, more was needed.

Our objectives for a remote monitoring system had now gone beyond just knowing the boat

still remained where we left it. While

there are other sensors we might add once we proved out the chosen system,

initially we wanted to know about these high priority items when away from the boat: (1) house battery voltage;

(2) shore power connection status; and (3) bilge water level. Likewise, when any measurement varied from a defined allowable range, we wanted to be

immediately notified via email or SMS text message so that intervention,

troubleshooting and remediation could begin sooner rather than later.

The “why” behind all of this is pretty straightforward – for instance, letting a house battery bank deplete to too low of a charge level (due to loss of shore power or a charger failure) could cost us around $5,000 USD for six new 8D AGM batteries. Similarly, rising water levels in the bilge cavity could indicate seawater intrusion (say, from a failed thru-hull), something with which we have some nasty and expensive experience. An early alert system of some sort would be much more cost effective than just crossing our fingers and hoping for the best. Obtaining a truly decent ROI on any boat project is about as rare as an honest politician, so if we could actually find one then it merited pursuit.

The “why” behind all of this is pretty straightforward – for instance, letting a house battery bank deplete to too low of a charge level (due to loss of shore power or a charger failure) could cost us around $5,000 USD for six new 8D AGM batteries. Similarly, rising water levels in the bilge cavity could indicate seawater intrusion (say, from a failed thru-hull), something with which we have some nasty and expensive experience. An early alert system of some sort would be much more cost effective than just crossing our fingers and hoping for the best. Obtaining a truly decent ROI on any boat project is about as rare as an honest politician, so if we could actually find one then it merited pursuit.

|

| Our Initial Monnit Purchase: Two Remote Voltage Sensors, Plus the Cellular Gateway Pictured with its Removable Antennae and Power Plug. After Initial Testing We Added Two More Sensors. |

Our

system requirements included (1) a modular system where sensors could be added

when/as needed; (2) a 4G LTE cellular gateway transmitter with its own SIM

card to send notifications (U.S. based would be OK for now); (3) completely wireless sensors, preferably

talking to the gateway in the 900 MHz radio frequency band for reliable wireless

signal range; (4) a wide selection of said sensors for both current requirements and

future expansion; (5) web-based and smart phone user interfaces for system administration

and sensor reading access; (6) a price point

that provides a reasonable ROI….preferably under $1,000 (USD) for equipment

outlay plus low-to-no subscription fees; and (7) a track record of quality and

reliability, with decent online support.

Our

4G connectivity and wireless sensor requirements eliminated well over half of

the potential field, leaving only a couple of contenders. And a few more were priced in the “marine

tradition” – i.e., if intended for a boat it must be unreasonably expensive. We finally settled on a brand called Monnit™ (LINK), which oddly enough does

not advertise its system for marine / vessel use, but boasts a fairly robust

industry footprint among food services, data centers and general facility

management. We were also hopeful their

client landscape would lend some staying power vs. some of the specialty (and

over-priced) marine monitor systems that have flamed out or fallen behind the

tech curve in recent years.

We

were concerned most of all with the effective range of any water detection sensor in

the bilge cavity, since that is deep within the bowels of the boat and closed

off by a very well insulated engine room. Bench-testing the Monnit equipment back at the condo over

75’ distances and using closed metal

closet doors had produced good results, and we weren't disappointed when it came to the real world install on the boat. The sensor transmission strength signals remained strong regardless of where we stuck the things.

Observations, Challenges &

Concerns

Setting

up the Monnit Gateway device was easy and straightforward, as was registering

each of the individual wireless monitors so that they became part of the

desired monitoring network. The same was

true for defining allowable measurement ranges and monitoring intervals. The browser-based configuration and reporting utility takes some getting used to, but with some practice it didn't take long to learn how to navigate and use it for system administration.

Mounting and wiring each of the monitors was also fairly straightforward, although the one for the shore power tap required considerable sleuthing with the multimeter for a good tap-in location; and Rick had to attach (crimp and heat shrink) ring leads to the bare wire ends of the battery voltage monitor. As an aside, monitoring for shore power presence wasn't exactly intuitive....see the "caveat" further down in this blog post.

Mounting and wiring each of the monitors was also fairly straightforward, although the one for the shore power tap required considerable sleuthing with the multimeter for a good tap-in location; and Rick had to attach (crimp and heat shrink) ring leads to the bare wire ends of the battery voltage monitor. As an aside, monitoring for shore power presence wasn't exactly intuitive....see the "caveat" further down in this blog post.

The

biggest concern going forward will be the sensor durability in the hot and

humid marine environment in SW Florida, where salt-laden air could eventually

affect any of the devices over time. The gateway won’t be of particular concern

as it lives in the protected pilot house. The bilge sensor should fare OK as

the sensor’s PCB and antenna are several feet above the actual water pickup

sensor, and the engine room tends to be a hot, dry place anyway. The house

batt and shore power sensors in the lazarette will likely have the most

continuous exposure to the salt air, although their locations are protected from

direct water sprays.

As an aside, we corresponded with the Monnit engineers on applying a thin coat of CRC Corrosion Block to the sensors, but they weren’t crazy about that idea. It also turns out they now have “Industrial” grade sensors with IP65 ratings which could likely last a good deal longer in the marine environment. We’d recommend (as do the Monnit engineers) that more expensive option if just starting out, but see pricing comments below.

It's also worth noting here that Monnit currently has two versions (what they call gen1 and gen2) of each sensor and you cannot mix and match them. We went with the gen2 versions branded as "Alta" since they boast improved circuitry and greater wireless range. The other unknown is sensor battery life - these use a 3V coin battery advertised for an average of two years of longevity, but only time will tell.

As an aside, we corresponded with the Monnit engineers on applying a thin coat of CRC Corrosion Block to the sensors, but they weren’t crazy about that idea. It also turns out they now have “Industrial” grade sensors with IP65 ratings which could likely last a good deal longer in the marine environment. We’d recommend (as do the Monnit engineers) that more expensive option if just starting out, but see pricing comments below.

It's also worth noting here that Monnit currently has two versions (what they call gen1 and gen2) of each sensor and you cannot mix and match them. We went with the gen2 versions branded as "Alta" since they boast improved circuitry and greater wireless range. The other unknown is sensor battery life - these use a 3V coin battery advertised for an average of two years of longevity, but only time will tell.

|

| The Shore Power Monitor (Yellow Arrow) Back in the Lazarette, Where We Tapped into the Inverter (Red Arrow) |

Conclusions

Overall our Monnit system has worked as desired and planned thus far.

We will want to figure out how to easily pause the monitoring

network when it’s not needed (e.g., while cruising and living aboard) so that

we don’t unnecessarily eat batteries, but that's a nit.

We’ll probably add some startup and shutdown actions to our existing

departure and arrival checklists. The web-based and smart phone remote access portals are also very good - see the screen captures at the end of the blog entry for some samples.

We also added a fourth sensor for the boat's cabin temperature, figuring it would be helpful to know if the air conditioning system takes a

dive even if everything else is humming along nicely. And for reference the whole thing still

came in around $700 USD. Using the aforementioned

“Industrial” grade sensors, which probably (in hindsight) would have been a

better idea, would add a premium to each sensor, so the total price

tag would be closer to our magic $1,000 threshold, especially once tax and shipping fees

are factored in. Also note the industrial versions use a Tadiran lithium battery which cost four times what a coin cell battery does, but theoretically also last four times longer.

Some other notes on subscription fees and cellular communications: With the Monnit system the

standard sensor heartbeat interval is 120 minutes with sensor readings at 20

minute intervals (6 per heartbeat span) and typically should be sufficient. There is a $10 per month data subscription fee for usage up to 1 MB, but there are no other extra fees unless you

exceed that 1 MB of gateway data ($5 for another MB, then $3 per MB thereafter.) Generally that shouldn’t happen unless you

let a sensor alarm keep triggering without intervention (which we discovered when testing the SMS and Email notifications.)

If shorter / faster “heartbeat” intervals are desired then the “Premier” service subscription at an additional $39 per year may make more sense but is still a reasonable price; that also provides a host of other more advanced functions which may or may not be of interest. As for the cellular portion, the chosen Monnit gateway uses an AT&T or Verizon SIM card, so it's fine for the U.S. where those carriers' coverage is decent. Other options exist (Ethernet or custom SIM gateways) so we suspect the Monnit solution would work elsewhere.

If shorter / faster “heartbeat” intervals are desired then the “Premier” service subscription at an additional $39 per year may make more sense but is still a reasonable price; that also provides a host of other more advanced functions which may or may not be of interest. As for the cellular portion, the chosen Monnit gateway uses an AT&T or Verizon SIM card, so it's fine for the U.S. where those carriers' coverage is decent. Other options exist (Ethernet or custom SIM gateways) so we suspect the Monnit solution would work elsewhere.

|

| The Temperature Sensor Tucked Away in the Port Aft Corner of the Pilot House |

There is another and nearly identical purchasing option at the "My BoatStatus" web site (see links below), a company who also source their devices from Monnit; they do carry inventory, but there you will find some price markups vs. the Monnit direct pricing. Other brands that were considered are listed near the bottom of this blog entry along with their associated web site links.

We’ll

provide periodic updates on the system’s reliability and durability, but

for now we are quite pleased with the result, and are calling the project a

success.

Caveats on Shore Power Monitoring

Wiring up this particular voltage monitor was a challenge, as how and where to monitor the AC voltage coming in from the shore power pedestal isn’t exactly obvious...at least it wasn't to Rick. This is partially due to Rick's grade school level of electrical expertise, but also to how the boat’s charger/inverter unit works.

When our (Xantrex) inverter is online and senses the presence of shore power current it simply goes into a pass-through mode and sends that power current to the boat’s AC distribution panel. But if/when shore power is interrupted it will automatically and immediately go into its inverter mode and start generating ("inverting") 120 VAC power from the 12 volt house battery bank, and pass that power to the AC panel. So monitoring for the presence of AC power downstream of the inverter unit is not particularly beneficial for this purpose. (You can put the inverter in “bypass” mode but you would have to accept that a loss of shore power would result in an electrically dead boat….that would be OK if you planned for an extended layup but otherwise would be problematic.)

One could also place the voltage monitor tap at a constantly powered 240 VAC circuit or outlet (the inverter only provides 120 VAC, the 240 VAC juice has to come from either shore power or the generator), but that’s not as easy as it sounds, at least not on Ghost Rider. The other alternative we eventually figured out was to just tap into the AC lines coming into the inverter, which is what we ultimately did. That tap is only on one of the two incoming 120V shore power legs, but that's sufficient for our purposes.

Other Competitors Considered

Other solutions considered but not pursued further include those listed below. There are probably others out there. Several of these

also include the GPS location and geo-fencing service within their monitoring solution, which we already had

installed via Trackimo and did not want to replicate:

➢ Boat Command….requires running wired cabling (LINK)

➢ Boat Nanny….acquired by GOST

➢ GOST….way too pricey for us (LINK)

➢ Kobelt….very sophisticated, requires N2K, could not find pricing (LINK)

➢ Kobelt….very sophisticated, requires N2K, could not find pricing (LINK)

➢ Simrad BoatConnect....also requires running wired cabling (LINK)

➢ Siren Marine….their wireless version is fairly new, good reviews, but pricier (LINK)

➢ Siren Marine….their wireless version is fairly new, good reviews, but pricier (LINK)

(* If you're already a Maretron user this "pricey" comment may not apply and would be worth evaluating further.)

What’s Next

Oh yes indeed, Rick already has another boat project in mind….this one to find a CCTV camera solution for visual monitoring of certain conditions / areas. Once again the desire is to find a mostly wireless solution to avoid tearing the boat apart to run cabling. It should be an interesting exercise.

Some Screen Shots

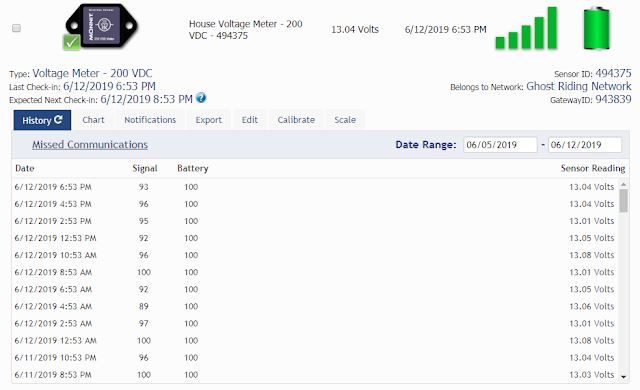

Here are some application screen shots, both from the iMonnit web portal as well as the included smart phone app. (Side note: their web portal sports two user interface experiences....Rick tends to favor the older "classic" look, but that's highly subjective.) At any rate, these are just a small subset of what's available:

Some Screen Shots

Here are some application screen shots, both from the iMonnit web portal as well as the included smart phone app. (Side note: their web portal sports two user interface experiences....Rick tends to favor the older "classic" look, but that's highly subjective.) At any rate, these are just a small subset of what's available:

|

| Screen Shot of the List of Notifications (Event Triggers) Defined for the Four Sensors and Gateway Device...from the iMonnit Web Portal |

|

| Screen Shot of Shore Power Sensor Readings from the iMonnit Web Portal |

|

| Screen Shot of House Battery Bank Sensor Readings from the iMonnit Web Portal |