|

| Looking Down Into the Bilge Cavity Which is Just Aft of the Main Engine, with a Water Hose Pumping Water In at a Pretty Good Clip. |

Still, even as we were enjoying the distraction and satisfaction of recently completing two special projects – for the boat’s remote monitoring and CCTV systems, see two previous blogs – we of course continued to pay attention to the periodic duties that Ghost Rider requires to stay (and keep us) happy.

It is not normal to wake up one morning and think “let’s see if we can flood the boat today”, but that’s essentially the

approach required when it’s time (annually) to test out the boat’s bilge

pumps. Ghost Rider has four of those as part of its de-watering

systems. Two are DC powered with

automatic float switches: a Whale Gulper 320 for nuisance water and a Rule 3100 for

high water, with 300 and 3,000 GPH ratings respectively. A third is manually operated via a hand pump;

that’s an Edson 638 with a gallon-per-stroke rating. And the fourth is a Pacer crash pump which can

evacuate up to 10,000 GPH – that’s about the volume of an average domestic in-ground

pool here in south Florida – and is hydraulically powered via the PTO coming

off the wing engine.

|

| The Hydraulic Pacer Crash Pump Located in the Lazarette. You Can Tell It's a Serious Pump by the Size of the Input & Output Hoses. |

And

the recently installed remote sensor dutifully reported its detection of high

water, but also revealed a weakness – it wouldn't dry out and

kept triggering alarms. After huddling with the vendor (Monnit) it was determined that we had a faulty unit and they shipped a replacement. Rick fashioned a new mounting method for this one (vertical vs. horizontal orientation, and a few inches lower) and thus far it is behaving. To illustrate we have added a couple of updated photos of the bilge area towards the bottom of this post.

As

mentioned in a previous blog we also needed to figure out what was wrong with

the master stateroom's air conditioning unit, which had started throwing “HI

PS” (high pressure) warnings and shutting itself down. After

a week of trying his home remedies with no resolution, Rick called an A/C tech

out to the boat; when he showed up as scheduled one morning, we cranked up the air

conditioning unit in the master stateroom….and it performed flawlessly.

No "HI PS" errors, just a constant flow of nicely

chilled air. We had the tech (Craig,

from VIP Marine, LINK) check

the system for pressure, component temps and overall system health – all of which

he pronounced to be sound. Puzzlement. Theoretically the issue could be a control board

about to go bad, or an intermittently sticking pressure switch, or just a piece

of flotsam that unstuck itself from the cooling loop…with the latter being the

most likely and preferable. But at any rate

the problem seems to be gone. Perhaps occasionally

you just get lucky.

|

| The Sea Strainer for the A/C with a New "Hat". Rick Ordered a Whole New Lid with Rubber Gasket for it After Experiencing Issues with the Old Cork Gasket. |

|

| The "Before" and "After" Pics of an Overhead Light Bezel (Trim Ring). It is Not a Difficult Task to Buff Out, but There Are 40 of Them. |

As it turns out, rubbing them down with a 3M Scotch Pad soaked with white vinegar restores them quite nicely and is a lot cheaper than buying new ones. But there are 40 of the damned things and that took a while given the difficulty of prying them off and snapping them back on. (After the first dozen or so we learned a useful trick: lightly coat the inside of the snap-on trim ring with Superlube synthetic grease… after which they became much easier to reinstall.)

|

| The Pilot House Overhead Panel (Removed) Where Water Was Leaking; the Red Arrow Points to the Sirius/XM Antenna Wire Feed That Was the Source. |

|

| The New (and Properly Caulked) Sirius/XM Antenna on the Roof of the Pilot House. With No Leaks. |

|

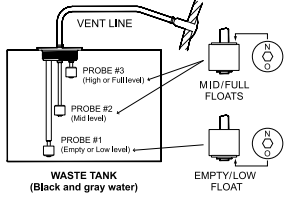

| The Top of the Black Water (Waste) Tank with the Yellow Arrow Pointing to the Tank-Level-Probe Assembly that Needs to be Removed & Cleaned Annually |

The device itself is dead nuts simple, with three adjustable level floats attached to a threaded top cap, and easy to remove (after labeling and disconnecting the four lead wires.) We then placed it into a large bag-lined bucket to (quickly) carry outside for a thorough hose down. We had replaced the original probe assembly with a new one when we first bought the boat, so it was in pretty good shape, easy to clean, and simple to reinstall. Rick followed up with a healthy shot of air sanitizer, also replacing the vent line charcoal filter, and those should not require attention for another year.

Lastly, it was obvious that Ghost Rider was in need of some TLC on its fiberglass exterior. While the light grey hull still looked good, above the gunwales was another story. Months of Florida sun and rain -- absent the daily chamois mopping since we were no longer living aboard -- left a lot of white fiberglass looking less than white; dirt stains were digging in. In between rain showers we spent several days of washing with Z-Tuff, removing tougher stains with Collonite fiberglass cleaner, followed up by applications of Collonite boat wax. In the exhausting and soupy heat of a south Florida summer it reminded us why we normally try to be elsewhere at this time of year.

|

| Ghost Rider Looking a Bit Cleaner While Comfortably Nestled in Her Slip at Legacy Harbour in Fort Myers |