Foreword: In 1787 Thomas Jefferson wrote to James Madison that “a little rebellion now and then is a good thing.” To date the USA has experienced two. The first created our constitution & the republic, with 25,000 American lives lost. The second in the 1860’s nearly ripped the country apart, took 655,000 souls, and failed. Those now trying for a third will lose, too, but there will still be a cost.

|

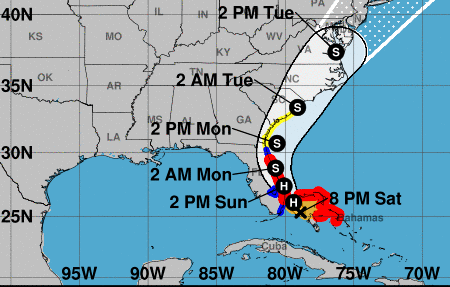

| The Drunken Path of a Confusing Storm |

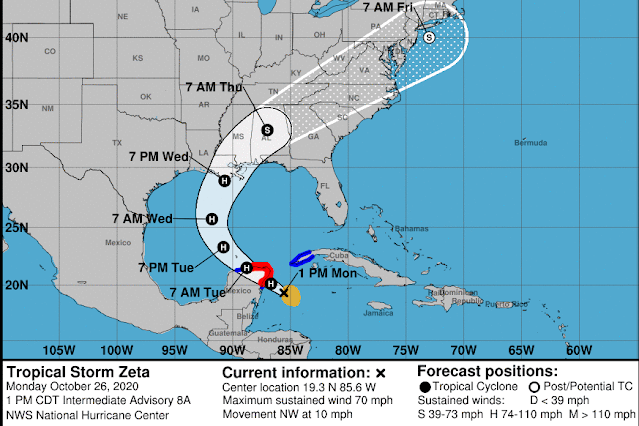

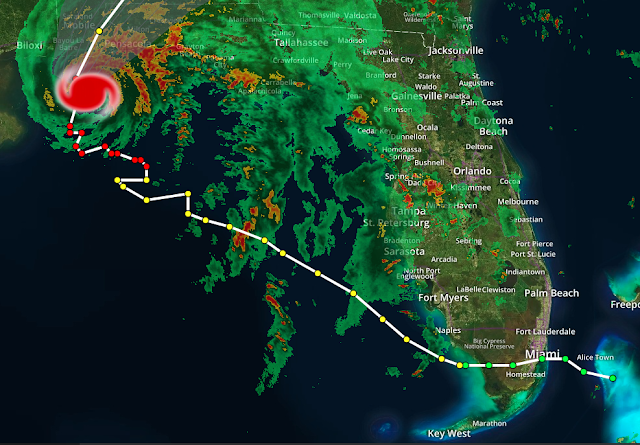

We had already deployed extra lines and fenders, so this time our preps were focused on securing canvas on the boat deck and flybridge, lowering antennae, and stowing all loose gear on the main deck into the lazarette. On the night of 08-November Eta passed about 80 miles to our south, bringing rain and occasional gusts to 45. After heading west into the Gulf of Mexico, then bending south before turning back to the northeast, Eta cruised past us again on 11-November, this time as a Cat-1 hurricane about 80 miles to our west. That brought us another round of rain and wind, with gusts up to 60 MPH, and an extra four feet of sea surge. It was an annoying way to celebrate our Veterans Day.

|

| Flybridge Cover Taped Down, Bimini Rolled Up & Non-fixed Antennae Lowered & Tied for Storm Preps |

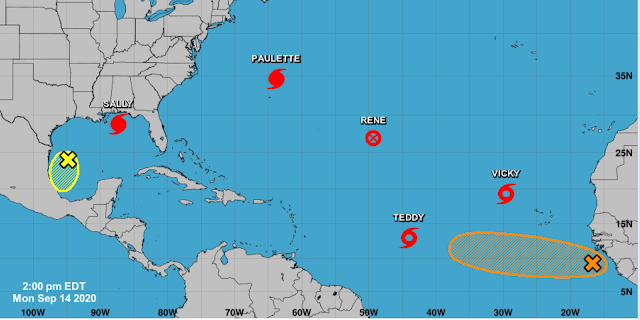

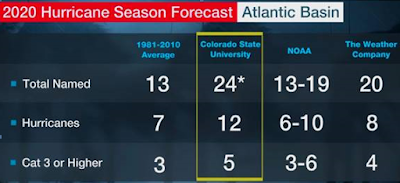

By the morning of 12-November Eta had made its fourth landfall just north of Tampa as it turned to the northeast, and proceeded to strafe the coastlines of Georgia and the Carolinas before continuing out to sea a few days later. We spent a day putting Ghost Rider’s gear back to a normal state, hoping we had seen our last tropical threat of the season. There was another forming down in the Caribbean again (which became Iota, a record-breaking 30th this year) but the long-term models did not predict a northern trek in our direction. Eventually Iota spun up into a Cat-5 and clobbered the same areas of Nicaragua and Guatemala that had been whacked by Eta on its first landfall two weeks prior. We count our blessings.

Break/Fix

Nothing broke this month. Honest. Really.

Regular Maintenance

It was a light month overall, and apart from the humdrum repetition of numerous, minor Wheelhouse preventive tasks, the main task this month was the bi-annual coolant flush for the wing engine. In addition to serving as our “get home” auxiliary propulsion unit, that Lugger 984 also powers the hydraulics for our bow and stern thrusters, in addition to the Maxwell 3500 windlass. It’s almost as important at the main engine, so we pay attention to its care and feeding requirements.

But unlike the generator and main engine diesels, we had never tackled a coolant system flush for that powerplant – our friends at Yacht Tech had handled the last one two years ago. Still, the principles were the same, so after a review of the technical manuals, Rick went after it. Overall it was pretty straightforward, with the main key being the use of the flexible “Form-a-Funnel” – actually two of them; otherwise we would have ended up with all the coolant in the bilge instead of a drain bucket. After that we flushed with fresh water until the drain ran clear and replaced the drain plug.

|

| Form-a-Funnels Make Draining Coolant a Much More Precision Operation |

While he was at it, Rick also attacked a thorough cleaning of the heat exchanger core, and even that turned out to be reasonably easy: remove the pencil zinc and drain plug, then both cap ends, take a wire rod and router it into each of the many honeycomb passages, pick out the old pieces of sacrificial zincs, and slap it all back together with a new pencil zinc.

|

| End Cap Removed on One End of the Heat Exchanger |

After adding back about three gallons of the Peak Fleet Charge 50/50 premix (the Luggers are picky about their coolant), the engine checked out under load with no leaks, and kept a steady 180F on the temp gauge.

Project Work

There was only one small project that we got to this month, and that was the annual detailing of the dinghy. To say the dinghy was dingy doesn’t quite cover it. Cleaning and waxing of the interior FRP surfaces was fairly straightforward, but scrubbing the Hypalon inflatable tubes took several passes with different cleaning solutions before it was anywhere close to acceptable.

Final (?) Tropical Weather Check

|

| Almost December & the Tropics Aren't Done Yet |

Departing the Boat

And lastly, the reconstruction efforts at the condo progressed far enough to make it sufficiently livable. Chelle had actually been spending more time there than on the boat – busy with project oversight and numerous complementary projects that dovetailed with the overall renovation scheme – while Rick had made a conscious effort to avoid most of the mayhem, enjoying the quiet of the boat. But by the time the Thanksgiving holiday rolled around most of the major work had been completed, and we both returned to dirt-dwelling.

|

| The Major Renovation Work Progressed Enough to Allow a Thanksgiving Back at the Condo |

Finally, a big thanks to our friends Martin and Stephanie Maurer aboard N60, Blossom, who stopped off at Legacy Harbour on their way from RFYC to their home in St. Petersburgh. They hosted us for two enjoyable evenings in the spacious open-air cockpit of Blossom, and the rare social experience was a wonderful break from the rigors of the pandemic.

With the arrival of December and south Florida’s version of winter, we’re now at a point where we may start contemplating what Rick calls “a different kind of boat.” But that’s an evaluation still in the very early stages, with more to come in the future. Stay tuned.

Afterword: During any

crisis the only thing more dangerous than a leadership void is blaming

conspiracy theories for those failures of leadership. That’s a downward spiral from which the

weak-minded never functionally recover. And from which pandemic victims get sick or

die. We’re supposed to be better than

this, but unlike previous generations, too many are proving they are not up to the challenges.