|

| Great Fun with Lots of Batts...Damned Things Weigh 65 Pounds Each |

Rick had plenty of time to plan the routes, which was fortunate as no two chart sets seemed to agree about the best routing through some of the shallow areas on the shoals and shallow banks. In the end we always deferred to the Explorer Chartbook sets, which – as their web site clearly and accurately states (LINK) – are the gold standard for Bahamas cruising.

A few other boats from our Grady-White club joined us for the adventure:

- Ron & Brenda Ingram on their 335 Freedom, Open View (plus 4 guests)

- Bob Chapman on his 335 Freedom, Dilly Dally (plus two guests)

- Tony & Carla Vandenoever on their 306 Canyon, Little

Bird

|

| Open View and Little Bird in Trail Behind Ghost Rider En Route to Key Largo |

And aboard Ghost Rider we were joined by Rick’s sister, Lin. So altogether we had 14 folks join the adventure, with planned stops at Key Largo (Florida), Chub Cay (Berry Islands), Cape Eleuthera, and Staniel Cay (Exumas).

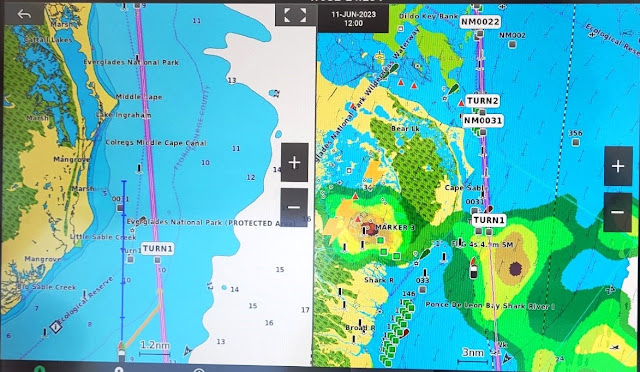

Sunday, 11-June: To Key Largo

The first day was all about getting to Key Largo in the northern Florida Keys, so we could stage our Gulf Stream crossing from there the following day. We rendezvoused at the Sanibel Causeway at 0900, with Open View and Little Bird falling into formation behind Ghost Rider (Bob on Dilly Dally had departed the day before) and headed south in perfect weather conditions – a warm, summery day with light breezes and flat seas, and only had to deviate slightly for one heavy shower in Florida Bay.

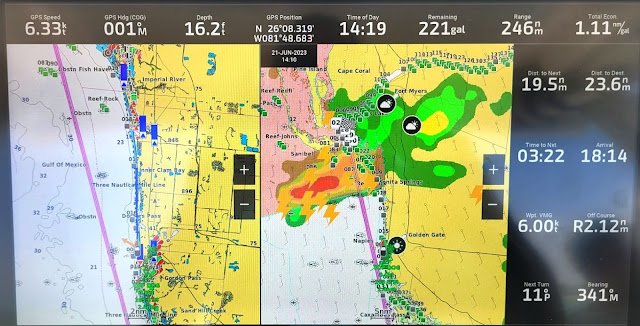

|

| The Weather We Dodged as Shown on the XM Satellite Display on the Right |

After clocking 155 nautical miles we were topping off fuel tanks in Key Largo by 1500, and then docking up at Marina Del Mar for the night. We enjoyed a group dinner at Skipper’s dockside restaurant, checked the next day’s weather forecast (good enough), enjoyed a night cap, and got some sleep.

Monday, 12-June: To Chub Cay

We were off the dock by 0800 and motoring east shortly thereafter. A few storms were draped along Florida’s southeast coast, but out in the open water we had good weather again. But sea conditions were pretty lumpy for the first half of the crossing – quartering off the starboard bow at 2 to 3 feet, with the occasional 4 footer tossed in just to juggle your eyeballs a bit. Initially that required deploying full trim tabs, but eventually the 15K winds clocked around to a southwesterly flow, and the ride improved (much to sister Lin’s relief.) After we cut through the shoals at South Riding Rock (about 20NM south of Cat Cay), the ride improved even further. We managed our route to bisect a couple of small thunderstorm cells shortly thereafter, and arrived at Chub Cay at the southern tip of the Berry Islands around 1430.

|

| The Long and Rather Bumpy Leg from Key Largo to Chub Cay |

The check-in process there was chaotic –

an impressive thunderstorm lashed the area shortly after our arrival, systems

were slow and the Internet was sclerotic.

Eventually we got a ride to customs and immigration located at the

nearby airport, after which we took down the Q-flag and raised the Bahamian

courtesy flag. We had dinner on the boat

and crashed for the night.

|

| It Stormed Heavily Shortly After We Arrived at Chub Cay |

Tuesday, 13-June: To Cape

Eleuthera

All boats spooled up at 0745 and headed

to the fuel dock to take on more fuel before the next 102 NM leg to Eleuthera. The Chub fuel dock was rationing, limiting

each boat to 120 gallons, but that was more than enough for the day. By 0900 we were underway again and headed

southeast through 2-3 foot seas and sunny weather towards New Providence Island

and Nassau, the capital of the Bahamas.

We skirted around Nassau Harbor via a skinny passage appropriately

called “The Narrows”, going from a few thousand feet of depth to a section of

the Great Bahama Bank that averaged about 14 feet deep – except where coral

heads sprout upward to just a few feet below the surface.

|

| Our Path From Chub Cay to Cape Eleuthera |

But we managed to keep the boats off the

bottom, and cut through another narrow passage at Highbourne Cay to cross over

into Exuma Sound, where depths once again were measured in thousands of

feet. From there, a 25 NM jog to the

northeast brought us to Cape Eleuthera around 1330. Tony and Carla in Little Bird went

about 10 NM further to the northeast for their lodging in Rock Sound.

Cape Eleuthera is a large, well-protected and deep harbor. Its fixed, wooden docks were in good condition, and all facilities – guest cabins, pool, beaches, restaurant, laundry and showers – were equally well kept. We spend a couple of relaxing days here enjoying the two beaches and pool (it was hot) with a side trip into town (not much there), and a group dinner at the marina restaurant (good food.)

|

| An Aerial View of the Cape Eleuthera Marina Basin |

|

| The Group Dinner at Cape Eleuthera's Harbor Point Restaurant |

On the second day we took Ghost Rider about 10 nautical miles to the south, near Davis Harbour on the west side of Eleuthera, to check out the fishing. In that area the water depths drop off sharply very close to the shoreline, and trolling the ledges can produce some nice fish. We lucked into a swarm of bait-feeding sea birds and found ourselves with a double-header hookup. Whatever was on Chelle’s line bit the leader in half (Wahoo or Barracuda?), but Rick’s line produced a nice 30-inch Mahi.

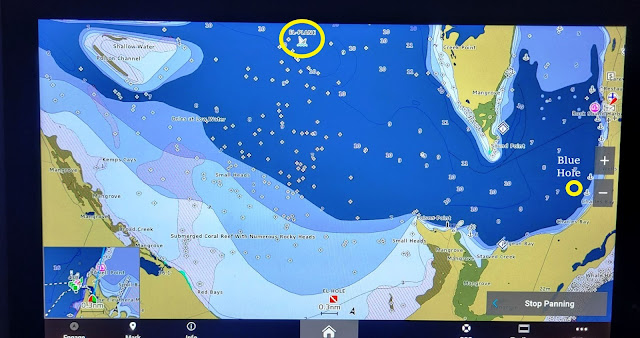

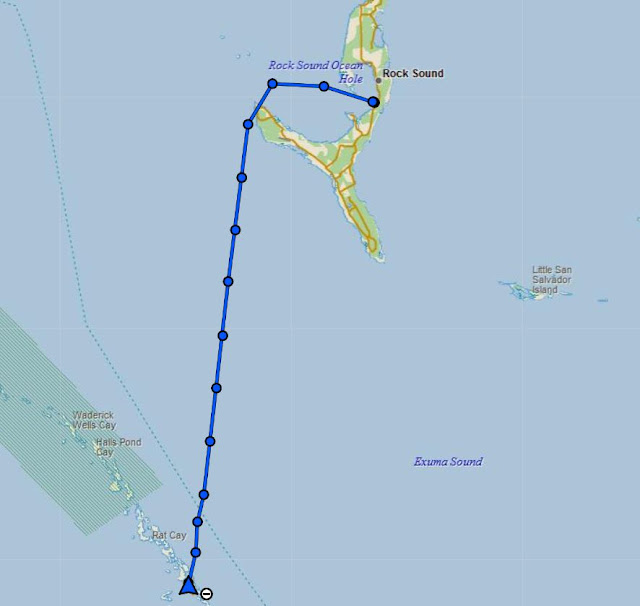

Friday, 16-June: To Staniel Cay

Since our next leg was a short one

(about 40 nautical miles to the southwest), after a mid-morning departure from

Cape Eleuthera we first diverted north and east about 10 miles towards Rock

Sound in search of a plane wreck site to snorkel. The GPS coordinates that Ron had provided

were accurate, and in 10 feet of very clear water the plane’s wings were easy

to discern, providing structure for a variety of sea life. From there we went a few more miles further

east into Rock Sound, in search of a “blue hole” that Bob noticed on the

Explorer Chart. It took a little dead

reckoning and all four boats in an impromptu search pattern, but eventually we

found it – a circular sinkhole depression in an otherwise flat limestone

seabed.

|

| The Yellow Circles on the Chart Display Mark the Plane Wreck & Blue Hole Locations |

The chart indicated the hole had a

16-meter depth (50 feet vs. the surrounding 6-8 feet). These holes occur all over the Bahamas, but

generally don’t feature much sea life, as they tend to be anoxic with poor

water circulation. As blue holes go in

the islands, it was quite modest – “Dean’s Blue Hole”, about 140 miles south of

this one, is the world’s second deepest at 660 feet.

|

| Snorkeling the Blue Hole |

Shortly after noon all boats retrieved

their snorkelers and we headed south and west to Staniel Cay in the Exumas

chain. In smooth water and pleasant weather

we were at Staniel Cay Yacht Club (SCYC) in under two hours. Once there, however, it took another hour to

get dock assignments and tie off – their staff and dock hands were definitely

on “island time.” Visitors should note that

the current absolutely rips through this area, and you can find yourself

drifting into very shallow shoals if you don’t pay attention.

|

| Our Track from Eleuthera/Rock Sound to Staniel Cay |

|

| An Aerial Shot of Staniel Cay Yacht Club (SCYC) |

Staniel Cay is a small island – about 1.7 miles in length, a half mile wide, just big enough for a 3,000 foot runway, with a small and mostly unprotected marina (SCYC) bolted on to its west side, and some small cottages perched on its steep slopes. It’s likely none of that would be here except for a few famous nearby attractions just to the north: the Thunderball Grotto, and Pig Beach on Big Major Cay.

Of the two, the grotto – a series of underwater caves – is definitely the better experience, and well worth the long journey to get there. Significant tidal flows and resultant currents don’t make that simple (wait for low tide and slack water), but once inside, it is rather stunning. We rented a small Boston Whaler skiff to make it less of a hassle, but even then the smooth limestone seabed makes setting an anchor in any kind of current a real challenge. You can read more about the grotto at this LINK, along with some of the movies filmed there (including its namesake 007 movie.)

Not far away, about a 1.5 mile boat ride

to the west and north, is Pig Beach (LINK). Uninhabited (well, except for the feral pigs

and transient touristas), Big Major Cay’s other significant draw is its large

anchorage, protected on three sides; dozens of monstrous yachts were moored

there.

As for Pig Beach, it would be more

accurate to call it Hog Beach, as most of the swine there are large and very

well fed, and definitely not shy; several of them were suitable for a riding

saddle. You can hand feed them, but if

you don’t and have food in hand, they will come and take it anyway (as sister Lin

discovered), without much regard for your desire to remain upright. And yeah, they can swim.

The next day we were planning to join Ron aboard Open View for some fishing in Exuma Sound, but the weather didn’t cooperate. Thunderstorms, with high winds and lightning, swept the area most of the day, and the boats got rocked pretty good by the southerly wind-driven waves. It turned out to be a good day for a nap in the air conditioned cabin. Since we were staying aboard the boat, and SCYC had no shower facilities, we made use of Lin’s cabin for nightly showers; while it was small, it was clean and bright, with a great view of the harbor area – she loved the idyllic setting. We had dinner at the marina restaurant one night (good food, but you had to submit your order by 1600 and reserve either the 1830 or 2030 seating schedule), but we otherwise prepared meals on the boat.

|

| Lin's SCYC Hillside Accommodations at the Chamberlain Cottages |

|

| And It Came with a Nice Water View |

The afternoon forecast for the Chub area wasn’t promising, so we got an early start at 0730, made our way back through the narrow cut into Exuma Sound, and scooted up the east coast of the Exuma chain until we got to Highbourne Cay. From there we joined the reversed route to Chub, cutting across the shallow banks again, back through “The Narrows” just east of Nassau, and from their motored in deep water to Chub. Seas were a little sloppy at 2-3 feet, but following off the stern. All boats topped off at the fuel dock (no rationing this time) and got tied up at the floating docks before storms raked the marina once again.

|

| Our Track from Staniel Cay Back to Chub Cay |

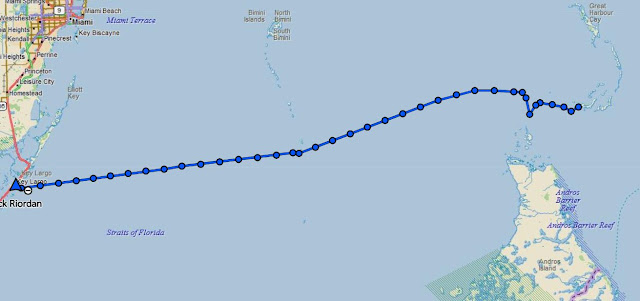

Tuesday, 20-June: Back to Key Largo

The weather and sea forecasts for the

return trip to US waters were looking very good, but all boats wanted to try

some fishing in the Chub area before making that dash….so we got started early

around 0730. The four boats fanned out into

the deep water – just east of the banks and north of Andros – known as “The

Pocket”, supposedly renowned for holding all sorts of pelagic fish. But as with our attempts last year, nothing

materialized over the next 90 minutes.

|

| Our Track Heading Back to Key Largo with a Deviation to Troll in "The Pocket" |

All four boats rendezvoused once again

at 0900 at the Northwest Shoal lighted marker, Ghost Rider took the

lead, and we headed west, making good time in smooth waters at 32 MPH (about 28

knots on the GPS). After crossing into

the deeper waters of the Gulf Stream through the Riding Rock cut-through, we

continued to encounter flat seas and arrived at the Largo canal entrance around

1445. Ghost Rider had no issues

taking on fuel, but the pump ran dry shortly thereafter so others had to head

one canal south to the Pilothouse Marina for gas. We had one last group dinner at Skipper’s and

then slept well.

|

| Flat Seas in the Gulf Stream Heading Back to Key Largo |

Wednesday, 21-June: RTB

This was RTB (return to base) day for

us, with the exception of Dilly Dally, as Bob planned to spend another

day or two with friends in Key Largo. Open

View and Little Bird sortied out at 0800 since they had a longer

distance to traverse back to PGI and Port Charlotte. Ghost Rider’s crew slept in a bit and

departed solo at 0900.

The run home was uneventful until we came abreast of Naples on the west coast of Florida around 1400, at which time both XM satellite weather and the radar set showed a healthy thunderstorm parked along our route near Fort Myers Beach. There was plenty of lightning visible, so Rick slowed the boat to a crawl to give the system time to either move or dissipate – he also thought he sighted a waterspout at the storm’s trailing edge near Sanibel at one point, but kept that to himself. (LINK to video).

|

| This Thunderstorm Could Not Have Parked Itself in a Worse Spot |

About

45 minutes later the storm had split into two cells and dissipated enough to

create an alley between them and the coastline that we could run without

concern. And by 1600 we had completed

our RTB (as had Open View and Little Bird). Bob in Dilly Dally returned home two

days later (also successfully dodging a thunderstorm along the way.)

Afterword

This was a fun and challenging expedition.

We thoroughly enjoyed the company of our fellow club members, the journey and the destinations. And as with most adventurous outings, preparation is as key as the doing. Anyone contemplating such an excursion is advised to spend at least twice as much time in planning readiness as in anticipated execution. Whether it’s customs and immigration requirements, or provisioning and spares, country-specific protocols, weather routing, charting and plotting, safety measures, pre-trip maintenance, whatever – there is plenty of prep and anticipation required. The fun is in pulling it all together and making it a smooth experience once underway.

By the way, Chelle did a terrific job of provisioning our boat and crew for the travels….we had plenty of libations, fresh water, food, clothing and basic supplies all the way….not an easy feat for liveaboards on a small boat in the Bahamas. She’s the expert for folks who want counsel on such things. And special shout-out kudos for her “Ever*Chill” instant ice-maker – that thing was totally awesome….one cannot enjoy good scotch or a Goombay Ghost without an ample and predictable supply of ice cubes.

|

| These Were All of the Charts Used to Plan & Plot the Trip |

Over the 11-day voyage we covered nearly 900 nautical (about 1100 statute) miles, consumed more than our fair share of scotch, rum and wine (after sailing hours at the dock, of course), and burned a lot of fuel – in Ghost Rider’s case, about $5,600 worth. We were happy to contribute to the American and Bahamian economies, and it was positively well worth it.

Our next sortie to the Bahamas will likely be back to the Abacos, timing TBD, more on that later.

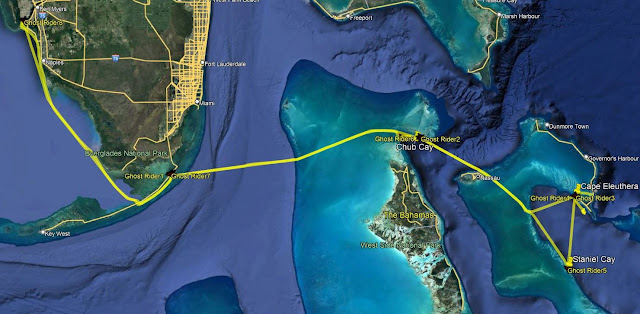

|

| We Exported Our Tracks from the inReach Tracking Site & Imported into Google Earth for This View of the Entire Journey |

Here are a few other pics from the trip....

|

| Sister Lin Enjoying a Smooth Run Enroute to Key Largo on Day 1 |

|

| Cape Eleuthera |

|

| Cape Eleuthera from the East Side (Sunrise Beach) |

|

| Lodging at Cape Eleuthera |

|

| At Cape Eleuthera Looking West at the Harbor Entry |

|

| Cape Eleuthera Pool Area at Sunset |

|

| Little Bird, Dilly Dally, Open View and Ghost Rider Docked at SCYC |

|

| The Chamberlain Cottages Near SCYC |

|

| Our Four Grady-Whites at SCYC as Seen from the Shoreline |