Foreword: We’re still observing our healthful

Covid protocols and staying safe, although here in Florida a lot of folks seem

intent on making that increasingly difficult.

Hurricane Isaias isn’t helping any, although thankfully we are not

directly impacted by that.

|

| The Aeroshell Aerobatic Team Flies Their AT-6 Texans with Beautiful Precision |

Apart from trying to keep the

boat clean, keeping up with routine maintenance, and occasionally exercising

engines and systems, our focus this month has been trying to find a fix for the

busted crane up on the boat deck. But first

we’re going to back up and start at the beginning of the month.

Independence Day!

As

a three generation military family every July 4th we appreciate and

enjoy our Independence Day celebration.

It’s a fabulous USA holiday that celebrates the beginning of a marvelous

experiment, albeit one in some jeopardy these days. We flew Old Glory both at the condo and the

boat all day, and respectfully retired the colors at sunset. In between we made sure we were at the marina

to witness the celebratory flyover by the Aeroshell Aerobatic Team (LINK), in their precision

fourship formation of AT-6 Texans directly over Ghost Rider. That vintage WWII aircraft (in service since 1938) is

the one in which Rick’s father learned to fly back in the early ‘40’s before

deploying to the Pacific Theater….and deserves its own salute. Short amateurish video below.

Regular

Maintenance

A

few days later it was time for our periodic “running of the diesels”, normally

not a routine with which we need to be concerned, but which is worth mentioning

during a time when so many boats and boaters (like us) are stuck in port. While Nordhavn vessels and their Lugger

diesels have proven to be largely indestructible, our goal is to minimize the

expensive service opportunities along the way.

Keeping systems exercised helps with that.

Just

running an engine for a few minutes does more harm than good – failing to bring

it all the way to the normal operating temperature range will just promote

internal condensation, corrosion and the early demise of both coolant and

oil. In reality that requires running

them for at least 30 to 45 minutes, and where possible under load.

|

| The Genset Instrument Cluster, with the Yellow Arrow Highlighting the Much Too High Temperature Gauge Reading of 210F |

That means activating as many engine-driven

systems as possible and exercising them as well. For the main engine that includes the

stabilizers and alternators, as well as bumping into gear for working the

transmission and packing gland. (You

want to be double-tied to very sturdy dock cleats for this part.) For the wing engine that entails running the

hydraulic thrusters. And for the

generator we disconnect from shore power and run full electrical loads. Finally, the steering system – helm pumps,

steering ram and autopilot pump – all get a short workout, too.

Break/Fix

Opportunities

During

the generator exercise period we noticed its coolant temperature gauge was

reading high – up to 210F, well above its optimum target of 185F (its thermostat

opens at 180F). Shooting the engine’s coolant

expansion tank with the infrared temperature gun confirmed that it was indeed

running at normal temp, so we knew we had some sort of gauge issue and not an

actual mechanical problem. (The genset

also has an internal fail safe switch that automatically shuts down the unit at

205F.) It was time for some sleuthing.

|

| The Back End of the Generator Where the Ground Wires Terminate. Yellow Arrow Indicates Gauge Grounding Bolt, Green is for the Bonding Wires. |

We

had learned from the Nordy owners forum that this wasn’t a particularly unusual

problem, and that just replacing the gauge rarely if ever resolved the

problem. While the sending unit was a

possibility, that wasn’t likely either – when that goes wonky, it’s usually a

total failure. It was much more probable

that one or more ground wires on the engine needed attention, and in the end

that proved true in this case. On our

L843 (12 KW) generator Rick eventually located two 10MM bolts securing a total

of three grounding wires plus three other bonding wire straps at the junction

box bracket. Disassembling those and

then thoroughly cleaning, sanding/filing, and then coating the ring terminals

with dielectric grease before reassembling did the trick. Rick also rearranged them a bit to isolate

the smaller grounding wires from the larger bonding straps.

|

| The Genset Instrument Cluster, with the Yellow Arrow Now Highlighting the Improved Temperature Gauge Reading of 190F Following Ground Wire Removal, Cleanup & Reattachment. |

The

genset’s temp gauge still reads slightly high compared to the IR gun reading,

but knowing that analog gauges aren’t particularly accurate in the first place,

we can live with it. (This is the reason

that in most cars you now mostly see either “idiot lights” instead of gauges,

or at best their gauges have rather wide pointer ranges in between “low” and

“high” pegs at the extremes. The gauges

with precise graduations are rarely better than false advertising, better to

treat them as trending indicators.)

Now,

about that busted crane. At the end of

last month’s blog post we mentioned that our Aritex HSC-610 davit had developed

an onerous problem – we traced a nasty hydraulic fluid leak to a corroded

reservoir tank in the base of the unit. Rick subsequently determined that it was

likely electrically related (electrolytic) corrosion….the green bonding strap

attached to the metal tank was carrying voltage and current according to the

multimeter, and that’s a problem. Rick pumped remaining hydraulic fluid out of

the tank, then spent a few afternoons reviewing manuals (which were mostly

useless) and trying to discern how to dismantle and extract the tank, motor,

manifold and control box; but without much success.

|

| The Crane's Hydraulic Motor and Tank Reservoir After Removal From Inside the Base. It Was Tight Quarters. |

We

learned from the marina office that Ross at nearby Classic Marine (who had very

capably handled our electronic throttle replacement last year) was experienced

with hydraulic cranes and davits, so we invited him out to the boat for a

look. He dug right in and had the motor

& tank assembly removed and on its way to his shop after about two hours of

sweaty persistence.

We’re

not exactly sure what the ultimate resolution may be, or when. For now Ross has agreed to work it in to his

busy schedule, but thus far hasn’t had any luck locating compatible replacement

parts. So we’re trying to look at

the bright side: at least it didn’t expire while we were trying to launch or

retrieve the dinghy. We still have no

idea what we would do about a crane failure with a 450 pound rigid inflatable

suspended from it, especially at some remote anchorage.

Project

Work

The next “future project” to bubble to

the top of the list was to upgrade the boat’s five Racor fuel filter

assemblies. Ghost Rider was originally built at a time that preceded today’s

ABYC and US Coast Guard standards for fire protection, which now specify filter

housings must either be all metallic, or the clear plastic ones should be

protected by metallic heat deflectors. The objective is to make them survivable

for a minimum of 2 ½ minutes in the event of an engine room fire, giving the

fire suppression system time to do its thing before a breached (melted) filter

could dump a full fuel tank into the blaze.

There’s a good explanatory article HERE

from Passagemaker.com.

Rick’s goal was to retrofit the Racor “MA”

series of heat deflectors to our old “FG” series of filters. On the surface that appeared straightforward

and less pricey than buying five new primary fuel filters. And, as usual, the reality turned out to be a

bit different. Research revealed that

the Racor fuel bowl design was changed in the 2002-2003 timeframe (when Ghost Rider was built), and the older

model bowls are not compatible with the MA heat deflector kits; there could be

differences both in thread sizes as well as the o-ring gland required to properly seal

the bowl’s new brass plug. But the only way to tell was to drain the bowl and

remove the old plastic plug.

Rick used one of the smaller 500FG

filters (for the wing engine) as an initial test, ordering the heat deflector

kit and a new bowl out of an

abundance of caution. As it turned out

the new bowl wasn’t needed, but Rick swapped it out anyway. He also had to remove the fuel lines, move an Algae-X filtering device, and add spacers between the filter housing the

engine room bulkhead to create enough room for the deflector shield…so it was a

bit more involved than originally anticipated.

Typical boat project.

|

| Removing & Replacing the Fuel Bowl on These Older Models is No Fun...the Upper Turbine Assembly Has to be Disassembled to Get That Done. |

Finally, Rick also added a brass on/off fuel valve (draincock), replacing the standard bowl plug, to make future draining both easier and less messy. To maintain conformance with ABYC fire standards that valve not only had to be metallic, but also could turn no more and no less than 90 degrees, could not rely on any spring tension for leak integrity, and also had to have its own plug as an additional measure against leaks.

We used the Racor Store (LINK) for the deflector kits and

bowl, and McMaster-Carr (LINK)

for sourcing the UL Listed fuel valves.

After running the wing engine for a spell and thorough leak-testing over

a few days we declared victory for the initial test. Rick proceeded to convert the bigger 900FG

Racor for the fuel transfer (polishing) system as a second test and that, too,

ended well.

In our August blog post we’ll report on

the efforts to convert the remaining three Racor filters (the two 900’s for the

main engine, and the other 500 for the generator.) And hopefully by then we’ll have a better

idea on next steps for the boat crane.

|

| Next Month We'll Get the Conversion Done for the Main Engine's Dual Racors (Far Left) and for the Generator (Far Right). The Latter Won't be Fun Because of the Algae-X Filter Below & Behind It. |

Afterword: We can't tell which disease is more dangerous, Covid-19 or Utter Stupidity. Either way, we have plenty of both down here. Back in March we accurately predicted the

havoc that results from a leadership vacuum, but it seems we underestimated the

additive impact of sociopathic idiocy. Historians

won’t be kind, and neither will our future generations.

|

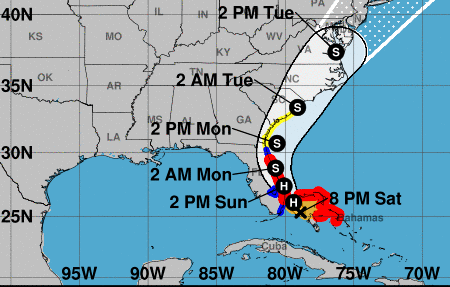

| Hurricane Isaias Stayed Off to Our East. Only Four More Months Remain in the "Season". |

Always fun to get the Newsletter and catch the latest. At least for this week you can be glad your not cruising the East Coast. The forecast track takes it to Maine, although I can't imagine it'll have a ton of MoJo by the time it either interacts with land or moves back out over colder water.

ReplyDeleteIt is obvious that the only thing we can control regarding this Pandemic is our own actions. We follow what Dr Birx (White House Coronavirus Task Force) recommended. "Treat everybody like they have it." We go about our daily activity with that in mind and just wear our masks everywhere.

If you and the Admiral want to stay safe and be stylin' at the same time, our Merch Dept will have Flying Toaster Face Masks in the next few weeks. (They are back-ordered at the moment.)

And we thought the Red Tide was bad 2 years ago....

Hey Bill,

ReplyDeleteOddly we made the decision to stay here in port for this summer about a year ago (planned condo renovation time), but yep, we’re happy to be here vs. over there. We have Nordy friends cruising the other coast, all scrambled for cover, and so far all are safe.

Your pandemic protocol is wise, stick with it, stay away from the conspiracy crazies. We’ll definitely take some Flying Toaster face masks when available, keep us posted on how & when.